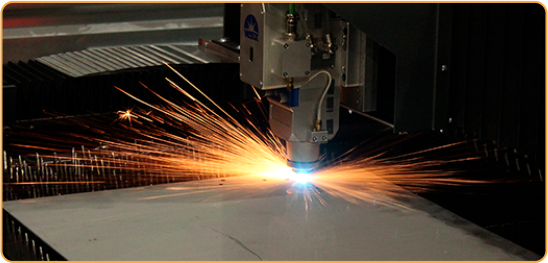

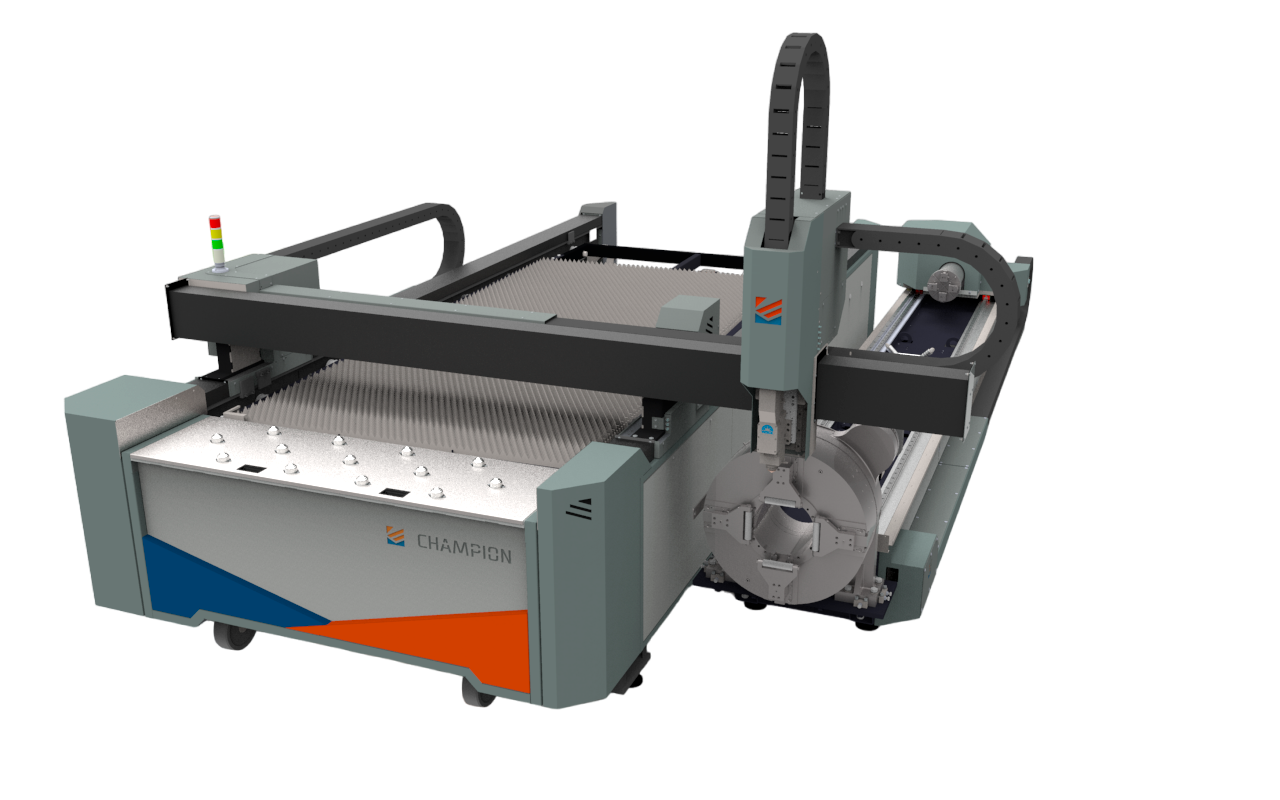

Champion Laser Machine with Tube Cutting Module

Made in Russia

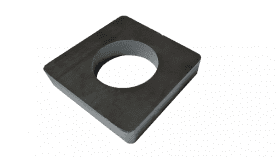

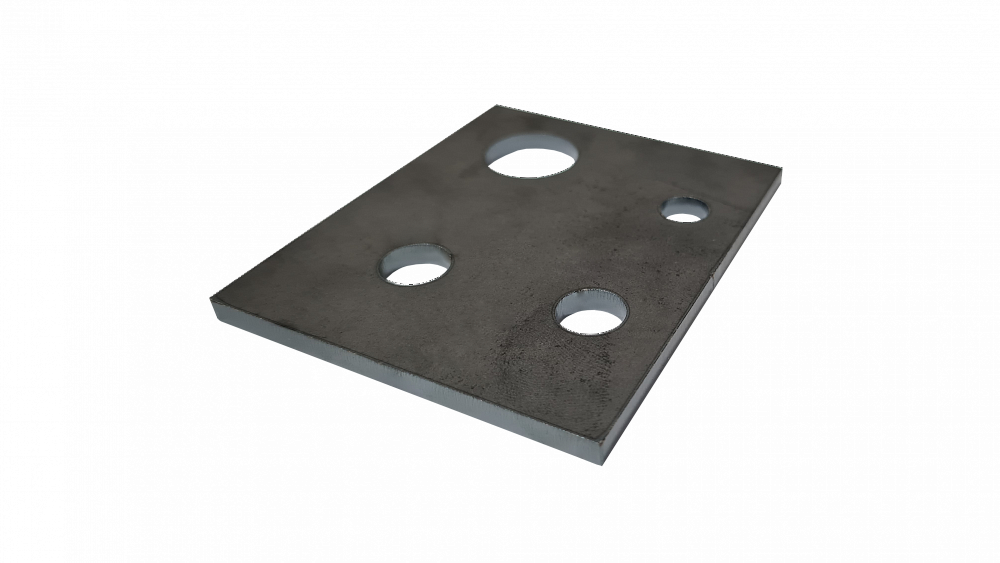

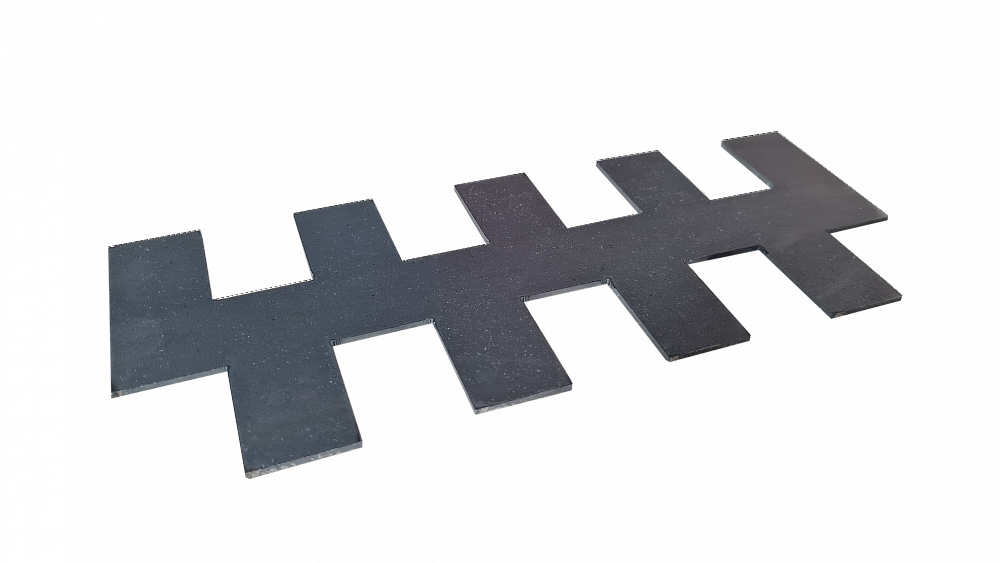

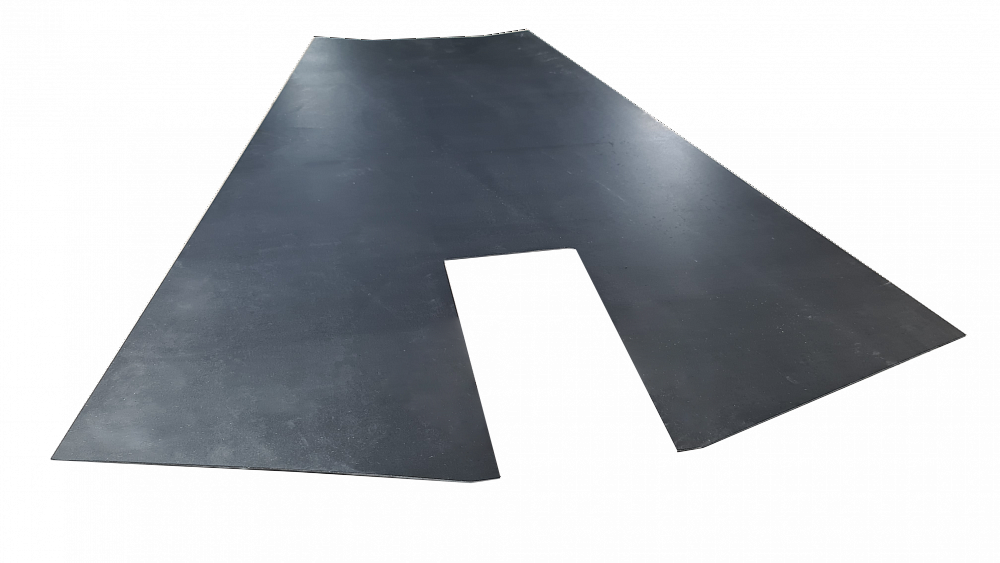

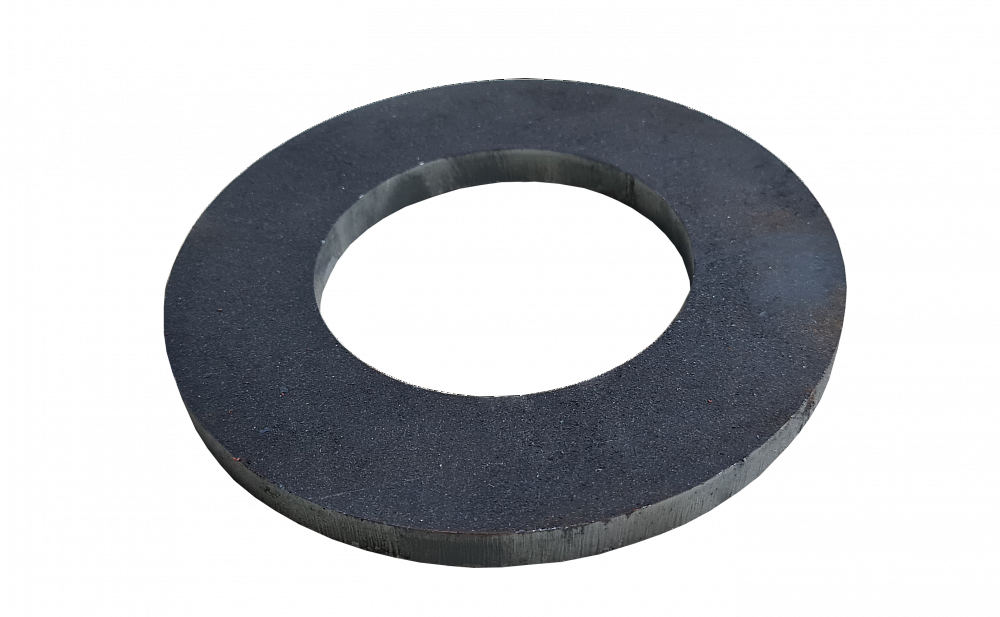

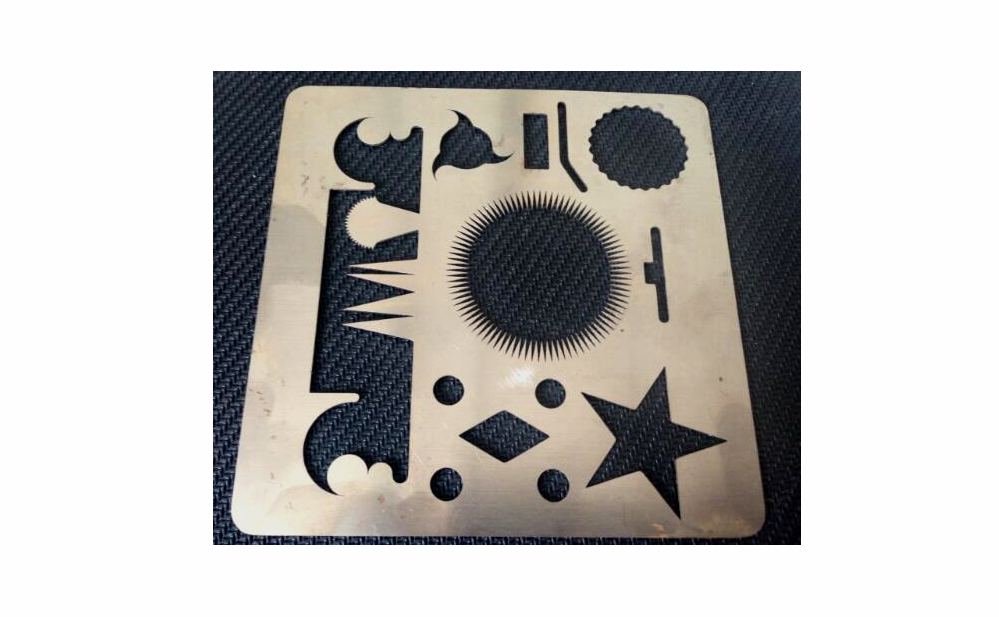

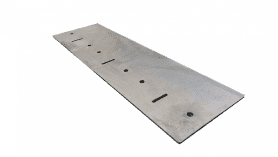

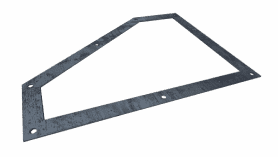

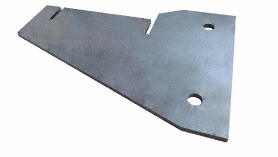

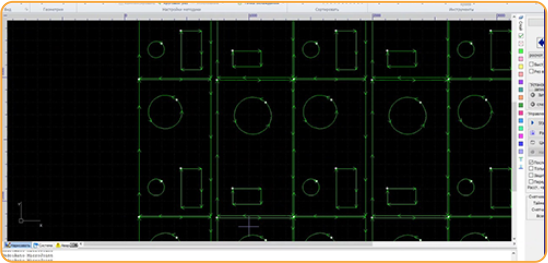

EXAMPLES OF METAL PARTS

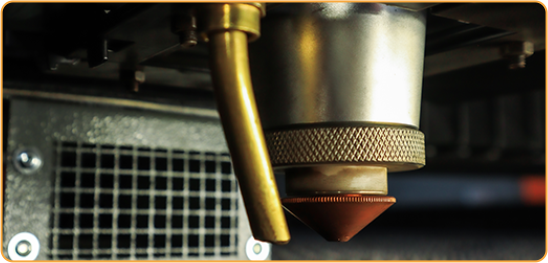

OUR INNOVATIONS

VIDEO ABOUT OUR FACTORY

Partners

40 dealers across Russia and the CIS

CHSZ products are in high demand, and more and more companies are becoming our partners. We are constantly working on improving the quality of our service and strive to make working with our products even more comfortable. Choose a reliable manufacturer of machines to achieve high results! Buy CHSZ CNC laser machines!

Model specifications

IN WHICH INDUSTRIES ARE LASER MACHINES USED

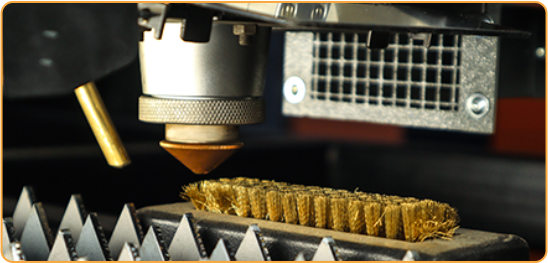

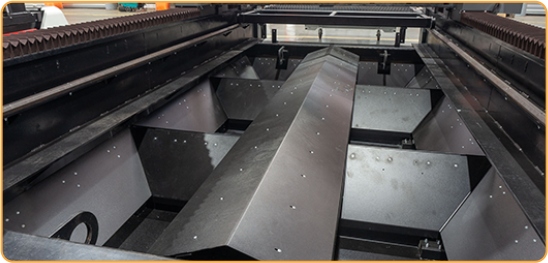

The CNC laser machine allows for the creation of complex geometric shapes from sheet metal, including artistic elements that require the highest precision in processing. Only one operator is sufficient to operate the laser cutting machine. The automatic exchange tables and retractable pallet make it easy to handle workpieces of different sizes, up to four meters in length! CHLEP specialists will teach each customer how to properly operate the machine.

SUBMIT AN APPLICATION

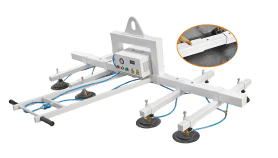

Options and additional equipment

History

2005

The company was founded by employees and graduates of the South Ural State University. Its history began in 2005 with the provision of metal processing services. Gradually, the enterprise grew, along with our capabilities and competencies. Design, technology, and development departments were also established.

2015

Since 2015, the company has significantly expanded its production capabilities by implementing modern machining centers, laser and coordinate-punching machines, CNC press brakes, and other equipment. CHSZ engineers started manufacturing chip conveyors, enclosures, and machine frames with numerical control.

2017

The team of developers, service engineers, programmers, and automation specialists has been expanded. The company began selling imported laser cutting systems.

2018

In 2018-2019, a fully functional prototype of a laser cutting machine was created, on which technology was tested, and high-quality components for serial production of laser cutting machines were selected and tested.

2020

In 2020, the in-house developed CNC laser cutting machine, CHAMPION, was launched into serial production.

2021

Since 2021, a new in-house developed laser machine, AVANGARD, has been launched into series production. The company's recognition as a market leader occurred at the international exhibition "Innoprom-2021", where CHSZ was officially represented as part of the delegation from the Chelyabinsk region. The products of the plant attracted great interest at the exhibition "Metalloobrabotka-2021" in Moscow.

2022

Chelyabinsk Machine-Building Plant participated in the "Metalloobrabotka-2022" exhibition in Moscow. They presented an improved version of the CHAMPION-3015 metal CNC laser cutting machine for the first time. The specialists of Chelyabinsk Machine-Building Plant paid even more attention to performance, reliability, and safety.

2023

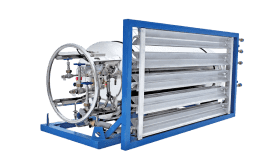

The enterprise is actively developing and expanding the range of products. This year, they introduced the Universal PROGRESS 3-in-1 machine for laser metal processing (cleaning, welding, cutting), the METEOR laser tube cutter, high-power laser machines, including those with a tube cutting module. CHSZ has improved the upper smoke extraction system of the CHAMPION machine.

Authorization Letter

Scientific and Technical Association IRE-Polyus confirms the authority of Chelyabinsk Machine-Building Plant to supply IPG equipment within the territory of the Russian Federation.