Avangard

Stay ahead with the AVANGARD CNC laser machine!

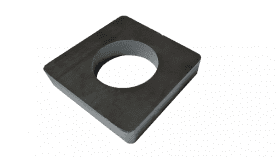

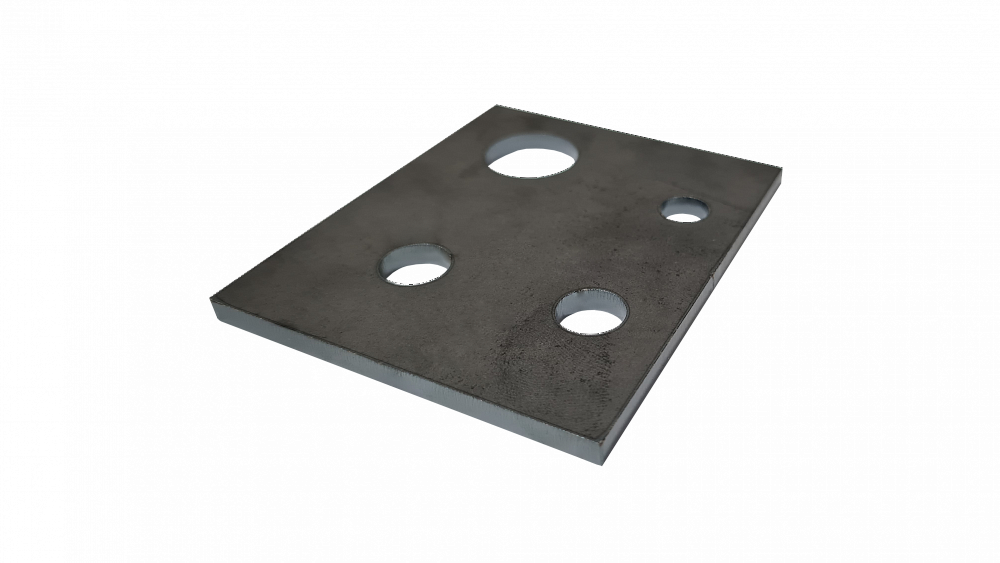

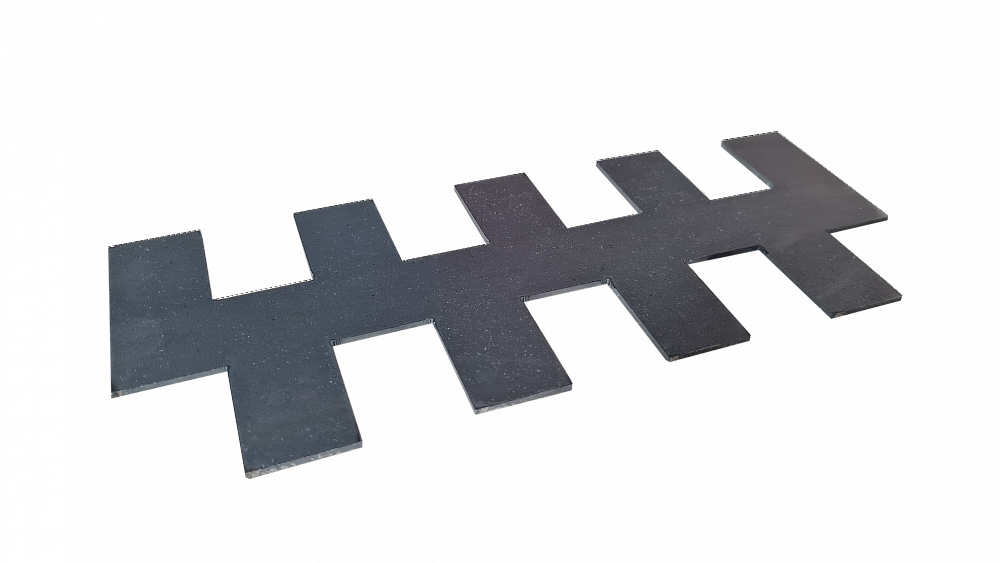

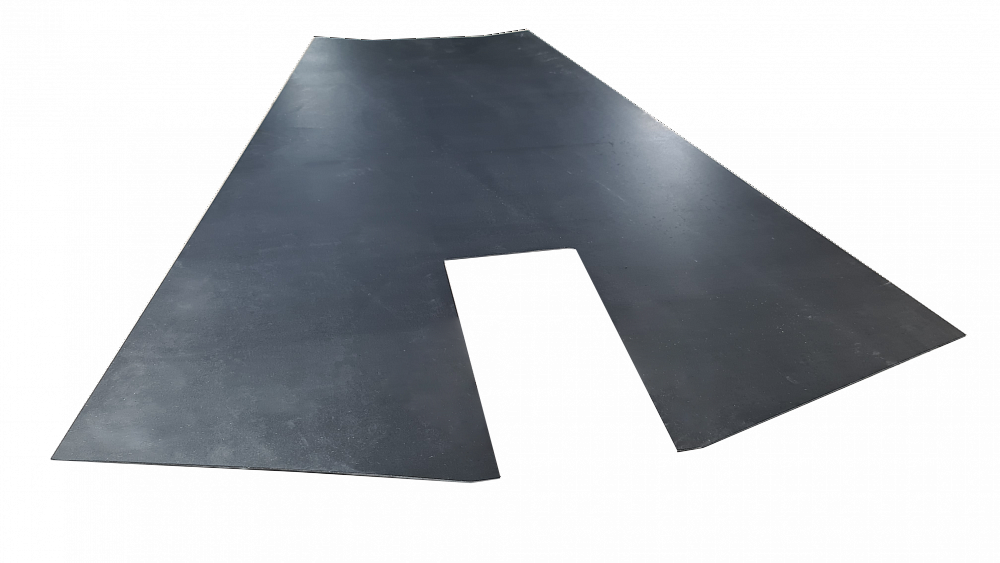

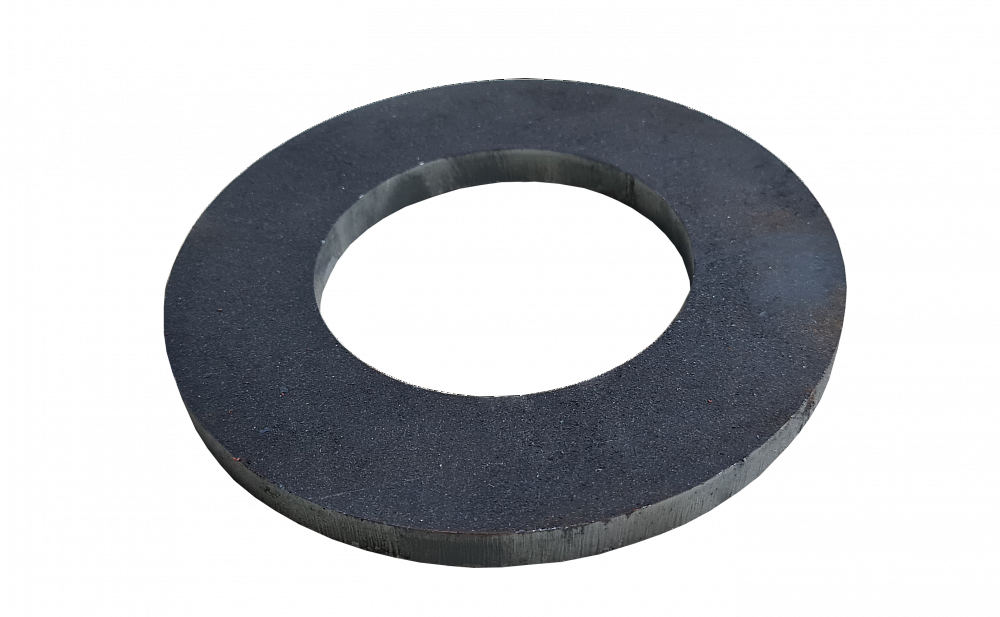

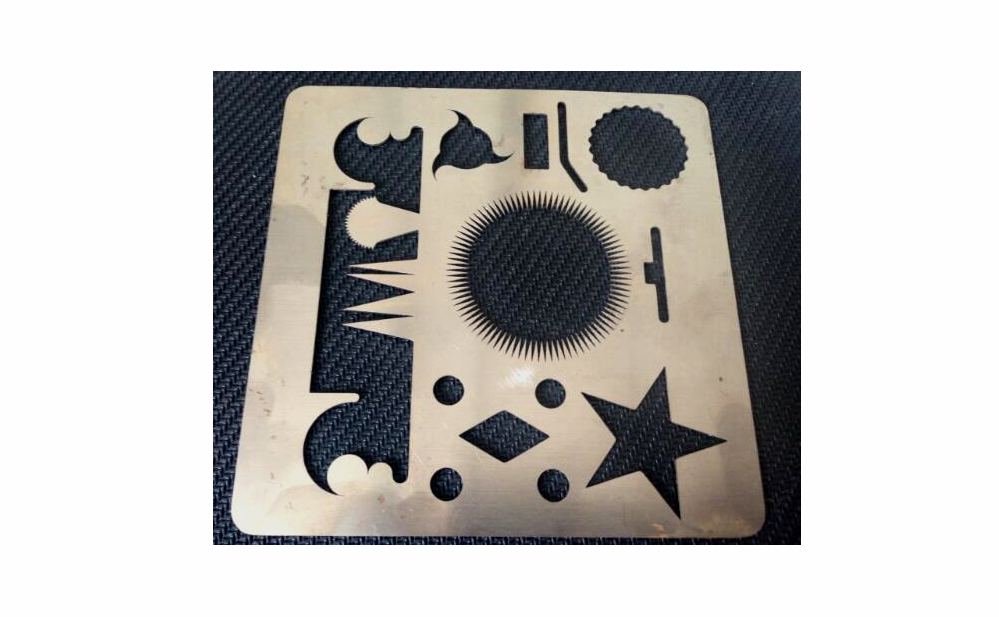

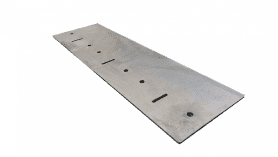

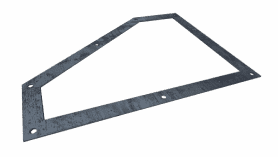

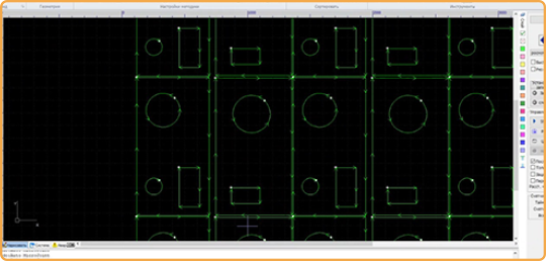

EXAMPLES OF METAL PARTS

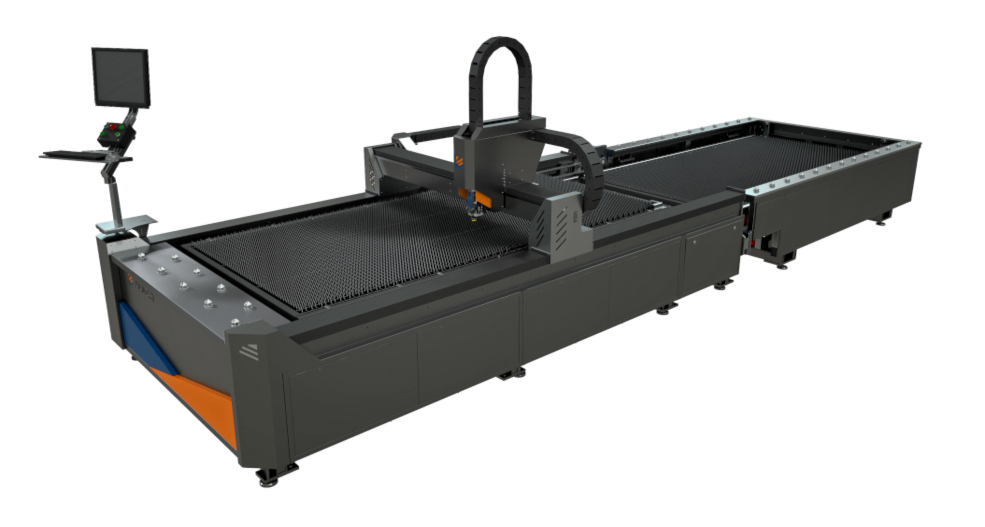

AVANGARD BASIC CONFIGURATION

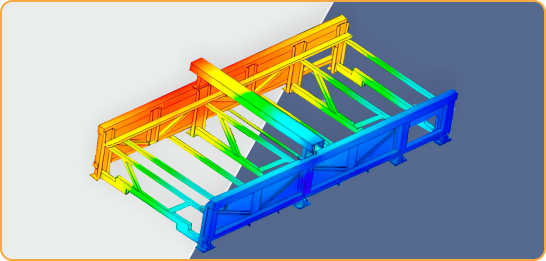

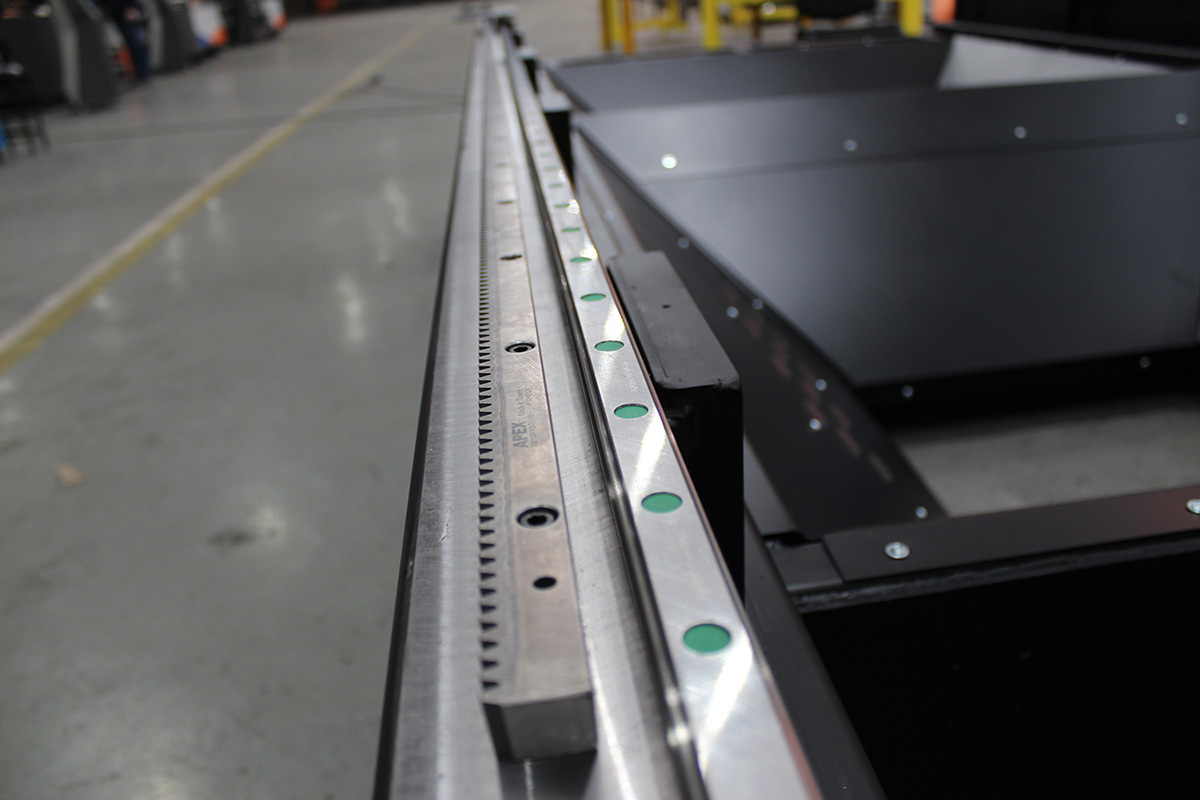

The AVANGARD machine is richly equipped with advanced components. It is based on a unique heat-treated steel milled frame with relieved stress. During machine operation, especially when working with thin metal, the frame vibration is significantly lower compared to machines with cast iron or welded frames.

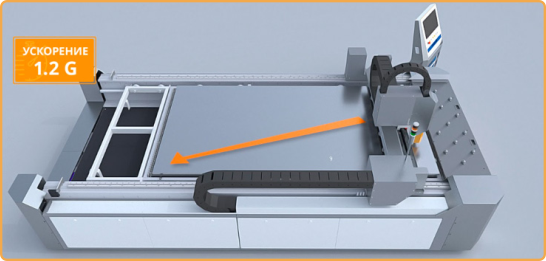

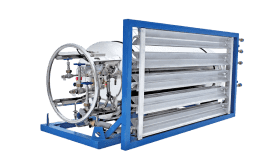

WITH AUTOMATIC EXCHANGE TABLES

The exchange table is designed for automatic pallet change with workpieces/parts in the machine's working area. The start of the pallet change cycle is initiated by the operator and it ends automatically.

OUR INNOVATIONS

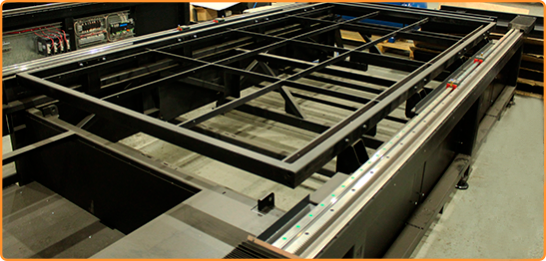

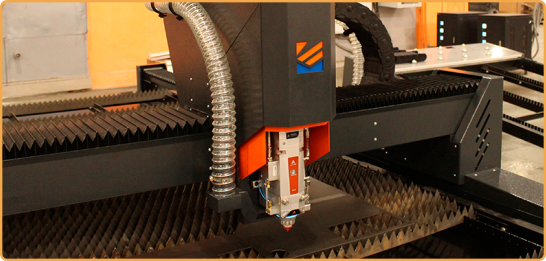

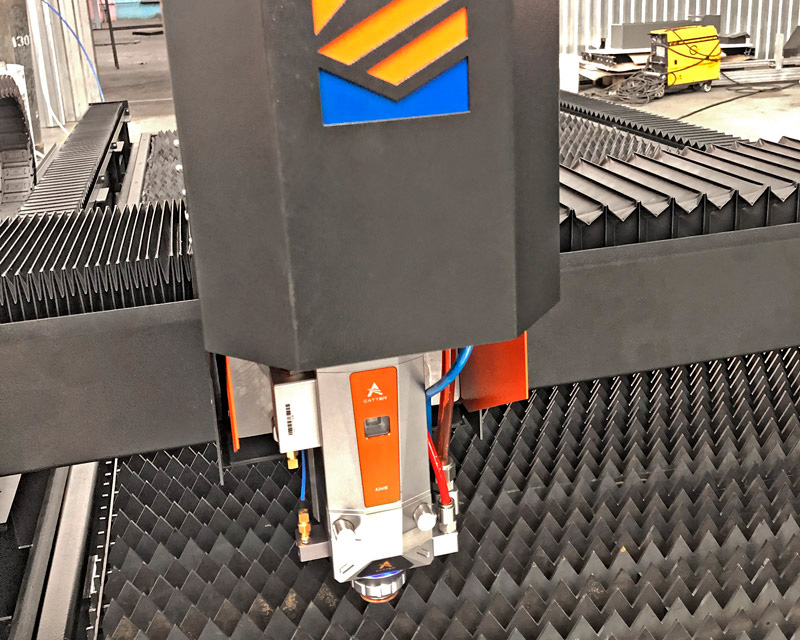

Photos of the machine

Capabilities of the Avangard

Comparison of AVANGARD machine

with chinese lasers

The frame and portal are made of the same material - steel. Over time, there will be no loss of accuracy due to temperature variations.

The frame is made of cast iron or steel, and the portal is made of aluminum. With temperature variations, the structure "tears itself apart." At a width of 2 meters, the values can be up to 0.3 mm, while the accuracy of the machines is claimed to be +/- 0.02 mm.

The frame is made of heat-treated steel.

The frame is not heat-treated, has a "liquid" structure, and cannot provide a reliable foundation for the dynamic operation of the portal.

Our speed is confirmed by both engineering calculations and actual tests.

The claimed speeds do not correspond to the applied drives - customer expectations are not met.

Wide-format screen for the operator.

Small or vertical.

Partners

Model specifications

IN WHICH INDUSTRIES ARE LASER MACHINES USED

SUBMIT AN APPLICATION

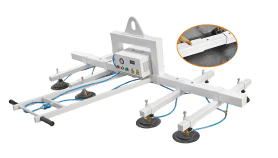

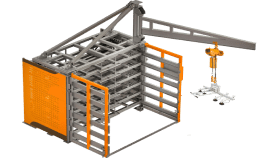

Options and additional equipment

History

2005

2015

2017

2018

2020

2021

2022

2023

Authorization Letter