Machine series

Champion

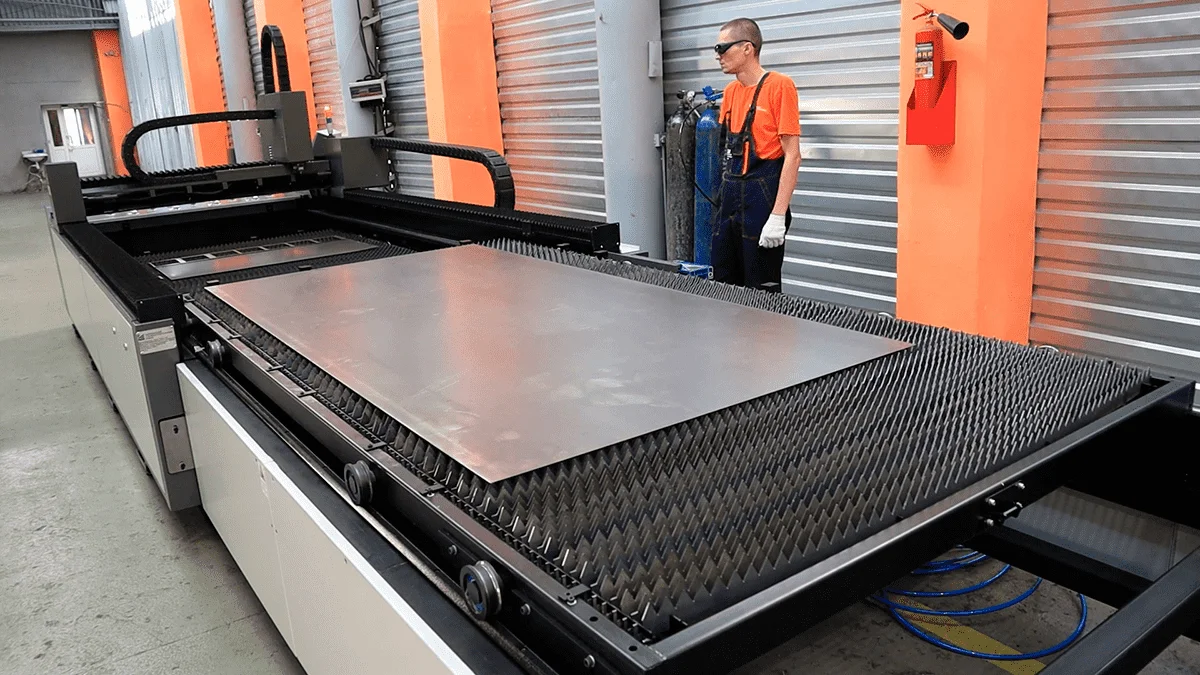

CNC laser machine from a domestic manufacturer

- Mineral-composite frame

- Maximum speed of 140 m/min

- Laser power up to 15 kW

- Minimal vibrations - allows for faster and more precise cutting!

- Working area: 3000x1500 mm; 6000x1500 mm; 6000x2000 mm

- Cuts sheet metal up to 30 mm

- Acceleration up to 1.5G

- New feature: possibility to equip with a Tube Cutting module

Avangard

Stay ahead with the AVANGARD CNC laser machine!

- Acceleration up to 1.2G

- Maximum speed of 100 m/min

- Laser power up to 3 kW

- Working area: 3000x1500 mm; 4000x1500 mm

- Cuts sheet metal up to 20 mm

Progress 3-in-1

Universal machine for laser cutting, cleaning, and welding - PROGRESS 3 in 1

- Made in Russia

- Power up to 3 kW

- Cuts metal up to 9 mm thick

- Cleans metal from rust, dirt, and paint residues

- Ability for welding and cutting steel, non-ferrous metals

- Touchscreen control

- Welding speed up to 8 times faster than arc welding

- Full penetration up to 4 mm thickness

- Dimensions (LxWxH): 1110x740x980 mm

Champion Laser Machine with Tube Cutting Module

Made in Russia

- Processing of sheet metal and tubes on a single machine

- Cuts tubes with an outer diameter of up to 250 mm

- Smoke extraction from the cutting area

- Processing of square, rectangular, oval-shaped tubes, channels, I-beams up to 6 meters and more

- Compact size

- The laser machine and tube cutter can be operated by a single operator

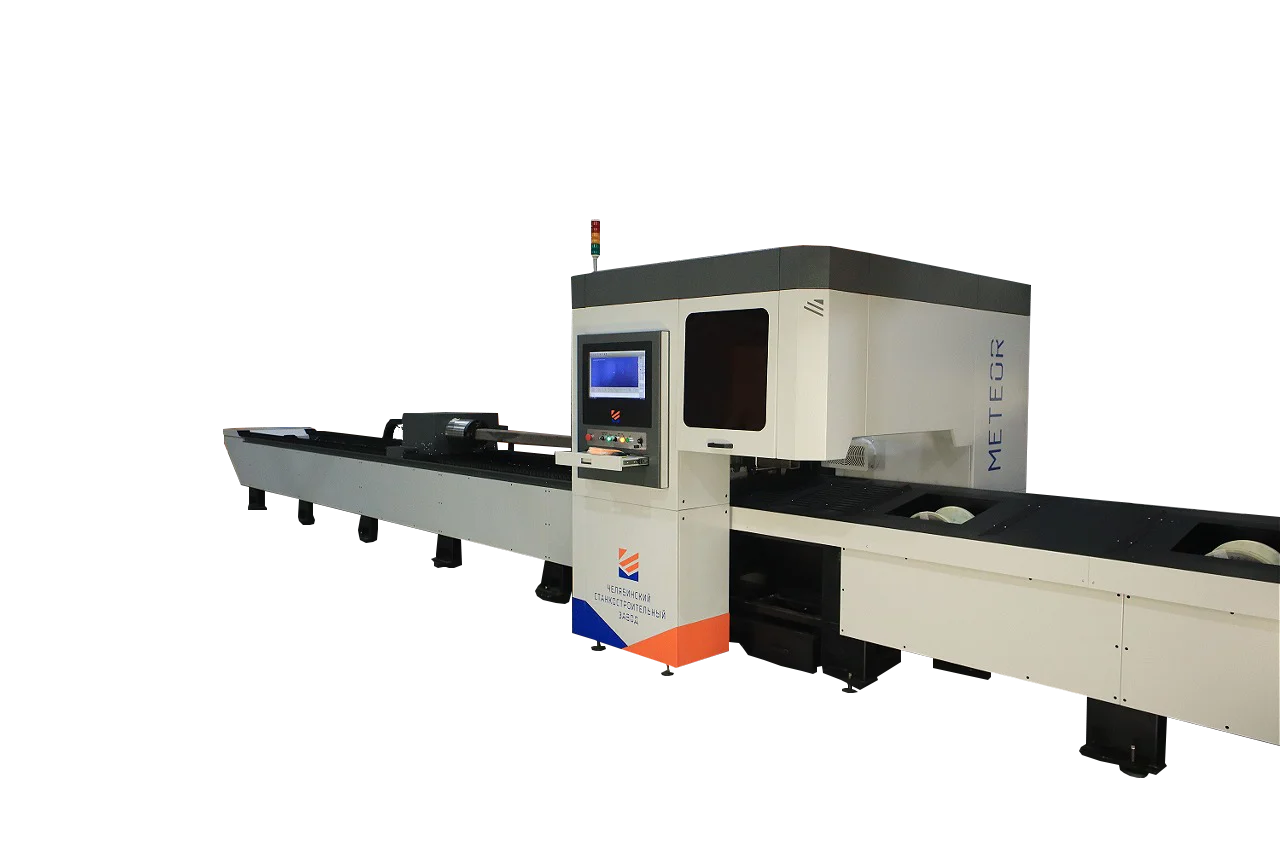

Meteor Laser Tube Cutter

For processing round and profile tubes, channels, I-beams

- Processing of tubes up to 6 m or up to 12 m in length

- Heavy mineral composite bed

- Smoke removal from the cutting area

- Smoke extraction from the rear chuck

- Tube movement speed - up to 50 m/min

- Laser head movement speed - up to 50 m/min

- Front roller support for the workpiece

Software

Chelyabinsk Machine-Building Plant machines operate on software with an intuitive interface.

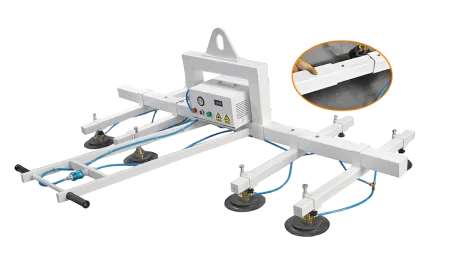

Additional Equipment

Optimize space in the workshop with additional equipment: vacuum lifters, cryogenic gasifiers, voltage stabilizers.

Automation around the machine

Speed up, simplify, and automate the feeding of sheet metal with the help of a console crane-beam and a compact rack with shelves capable of withstanding loads up to 6 tons.

OUR PRODUCTION

A GREAT

HISTORY

The company's history began in 2005 with the provision of metal processing services. It was founded by employees and graduates of the South Ural State University. Since its inception, the company has been successfully developing and constantly expanding the range of products it manufactures.

STRONG

PRODUCTION

Today, the CHSZ team consists of a powerful collective of professionals, which has allowed us to achieve a full production cycle and provide a high level of customer service. Our development department constantly improves its competencies, and our specialists implement new, unparalleled solutions in the market of laser metal cutting and related operations.

MUTUALLY BENEFICIAL

PARTNERSHIP

Chelyabinsk Machine-Building Plant provides quality service and completes work within short timeframes. Our main values are quality, professionalism, and friendliness.

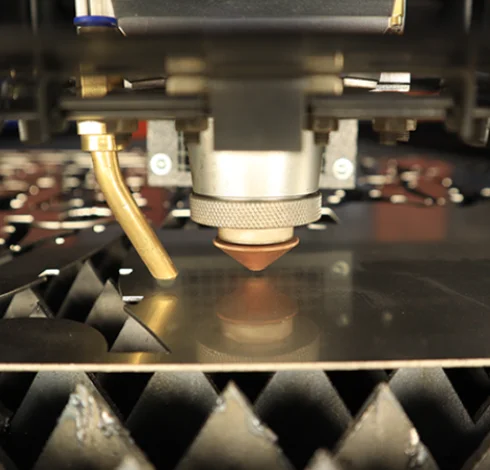

HOW ARE CNC LASER MACHINES CREATED?

Metal laser cutting machines are complex equipment, and the stability and quality of their operation are formed during the design stage.

Each component of the future machine is designed by specialists from the R&D department of Chelyabinsk Machine-Building Plant. A scientific approach and extensive research expertise allow for modeling the main elements of the machine to ensure their functionality and reliability. An important task during the machine design is to achieve a balance between its quality and cost indicators.

Paperless technologies are widely used in the design and manufacturing of machines. Based on the electronic documentation provided to the workshops of CHSZ, laser cutting of workpieces, bending of parts, welding, and painting of components are carried out.

The use of modern equipment ensures compliance with the design requirements for dimensional accuracy and shape.

The assembly and testing of the machine's electrical panels and the electrical drive system are carried out in the electrical equipment department of CHSZ. This allows for the identification of faulty elements before their installation in the machine.

The machine assembly takes place in the assembly workshop following the developed technology. Laser measuring systems are used to control the important geometric dimensions necessary for the machine's operation, ensuring precise operations with micron accuracy.

An important operation in creating the machine is its setup. The plant's specialists adjust the feed drive system, ensuring accuracy of movement, speed, and acceleration according to the specified requirements. After the drive system is set up, the machine undergoes a run-in period of at least 100 hours of continuous operation.

The machine assembly is completed with the installation of the laser cutting head and the laser radiation source, after which the machine is ready to perform its function - metal cutting. The plant's specialists test the machine during cutting various materials across a wide range of thicknesses. These tests are conducted under the supervision of quality control specialists.

Before being sent to the customer, all machine components that have lost their commercial appearance during testing are replaced.

Sound design, strict adherence to manufacturing technologies, setup, and testing of the machine allow our customers to receive products that meet the declared specifications and are capable of performing their functions with high quality for a long time.

Each component of the future machine is designed by specialists from the R&D department of Chelyabinsk Machine-Building Plant. A scientific approach and extensive research expertise allow for modeling the main elements of the machine to ensure their functionality and reliability. An important task during the machine design is to achieve a balance between its quality and cost indicators.

Paperless technologies are widely used in the design and manufacturing of machines. Based on the electronic documentation provided to the workshops of CHSZ, laser cutting of workpieces, bending of parts, welding, and painting of components are carried out.

The use of modern equipment ensures compliance with the design requirements for dimensional accuracy and shape.

The assembly and testing of the machine's electrical panels and the electrical drive system are carried out in the electrical equipment department of CHSZ. This allows for the identification of faulty elements before their installation in the machine.

The machine assembly takes place in the assembly workshop following the developed technology. Laser measuring systems are used to control the important geometric dimensions necessary for the machine's operation, ensuring precise operations with micron accuracy.

An important operation in creating the machine is its setup. The plant's specialists adjust the feed drive system, ensuring accuracy of movement, speed, and acceleration according to the specified requirements. After the drive system is set up, the machine undergoes a run-in period of at least 100 hours of continuous operation.

The machine assembly is completed with the installation of the laser cutting head and the laser radiation source, after which the machine is ready to perform its function - metal cutting. The plant's specialists test the machine during cutting various materials across a wide range of thicknesses. These tests are conducted under the supervision of quality control specialists.

Before being sent to the customer, all machine components that have lost their commercial appearance during testing are replaced.

Sound design, strict adherence to manufacturing technologies, setup, and testing of the machine allow our customers to receive products that meet the declared specifications and are capable of performing their functions with high quality for a long time.

KINEMATICS OF OUR CNC LASER MACHINES

The laser cutting machines produced by Chelyabinsk Machine-Building Plant are built on a classical kinematic scheme with three independent coordinates.

Thanks to the optimal selection of components, load modeling, and original design solutions, CHSZ offers machines that are at least comparable in characteristics to competitors but at more attractive prices. The calculated service life is at least 10 years when operating 24/7.

Analysis of laser cutting machine structures has shown that they often use components from well-known manufacturers, which can lead to some, sometimes significant, overpayment for the brand. However, the market offers products from lesser-known manufacturers with comparable characteristics.

Chelyabinsk Machine-Building Plant successfully cooperates with Nietz, a major manufacturer of electromechanical equipment from China. A wide range of servo drives and planetary gearboxes, which are comparable to renowned counterparts, as well as the ability to promptly manufacture components with the necessary customer parameters, allow us to create equipment with optimal accuracy and performance. To achieve optimal performance on each machine, CHSZ specialists adjust the parameters of the servo drives based on experimental data on the dynamic characteristics of the electromechanical system of each specific machine.

Modeling of static and dynamic loads occurring in the machine has allowed us to use smaller-sized rail guides compared to competitors without compromising the accuracy and durability of the machine. The use of pre-tensioned carriages has reduced positioning errors and improved smoothness of movement.

The combination of measures taken during the design and manufacturing of the machines has enabled us to establish serial production of equipment with high consumer characteristics: laser head travel speeds of up to 100 m/min or 140 m/min (depending on the model), accelerations of up to 1.2g or 1.5g (depending on the model), with cutting tolerances corresponding to grades 7-12.

Thanks to the optimal selection of components, load modeling, and original design solutions, CHSZ offers machines that are at least comparable in characteristics to competitors but at more attractive prices. The calculated service life is at least 10 years when operating 24/7.

Analysis of laser cutting machine structures has shown that they often use components from well-known manufacturers, which can lead to some, sometimes significant, overpayment for the brand. However, the market offers products from lesser-known manufacturers with comparable characteristics.

Chelyabinsk Machine-Building Plant successfully cooperates with Nietz, a major manufacturer of electromechanical equipment from China. A wide range of servo drives and planetary gearboxes, which are comparable to renowned counterparts, as well as the ability to promptly manufacture components with the necessary customer parameters, allow us to create equipment with optimal accuracy and performance. To achieve optimal performance on each machine, CHSZ specialists adjust the parameters of the servo drives based on experimental data on the dynamic characteristics of the electromechanical system of each specific machine.

Modeling of static and dynamic loads occurring in the machine has allowed us to use smaller-sized rail guides compared to competitors without compromising the accuracy and durability of the machine. The use of pre-tensioned carriages has reduced positioning errors and improved smoothness of movement.

The combination of measures taken during the design and manufacturing of the machines has enabled us to establish serial production of equipment with high consumer characteristics: laser head travel speeds of up to 100 m/min or 140 m/min (depending on the model), accelerations of up to 1.2g or 1.5g (depending on the model), with cutting tolerances corresponding to grades 7-12.

VIDEO ABOUT OUR FACTORY

WHERE DO THE CHSZ CNC LASER MACHINES WORK

Partners

40 dealers across Russia and the CIS

CHSZ products are in high demand, and more and more companies are becoming our partners. We are constantly working on improving the quality of our service and strive to make working with our products even more comfortable. Choose a reliable manufacturer of machines to achieve high results! Buy CHSZ CNC laser machines!

History

2005

The company was founded by employees and graduates of the South Ural State University. Its history began in 2005 with the provision of metal processing services. Gradually, the enterprise grew, along with our capabilities and competencies. Design, technology, and development departments were also established.

2015

Since 2015, the company has significantly expanded its production capabilities by implementing modern machining centers, laser and coordinate-punching machines, CNC press brakes, and other equipment. CHSZ engineers started manufacturing chip conveyors, enclosures, and machine frames with numerical control.

2017

The team of developers, service engineers, programmers, and automation specialists has been expanded. The company began selling imported laser cutting systems.

2018

In 2018-2019, a fully functional prototype of a laser cutting machine was created, on which technology was tested, and high-quality components for serial production of laser cutting machines were selected and tested.

2020

In 2020, the in-house developed CNC laser cutting machine, CHAMPION, was launched into serial production.

2021

Since 2021, a new in-house developed laser machine, AVANGARD, has been launched into series production. The company's recognition as a market leader occurred at the international exhibition "Innoprom-2021", where CHSZ was officially represented as part of the delegation from the Chelyabinsk region. The products of the plant attracted great interest at the exhibition "Metalloobrabotka-2021" in Moscow.

2022

Chelyabinsk Machine-Building Plant participated in the "Metalloobrabotka-2022" exhibition in Moscow. They presented an improved version of the CHAMPION-3015 metal CNC laser cutting machine for the first time. The specialists of Chelyabinsk Machine-Building Plant paid even more attention to performance, reliability, and safety.

2023

The enterprise is actively developing and expanding the range of products. This year, they introduced the Universal PROGRESS 3-in-1 machine for laser metal processing (cleaning, welding, cutting), the METEOR laser tube cutter, high-power laser machines, including those with a tube cutting module. CHSZ has improved the upper smoke extraction system of the CHAMPION machine.

Authorization Letter

Scientific and Technical Association IRE-Polyus confirms the authority of Chelyabinsk Machine-Building Plant to supply IPG equipment within the territory of the Russian Federation.